Another beautiful day. We took a long walk and played on the playground this morning, then finished up all my pre-winter chores (except getting the garage organized) this afternoon. This weekend was great, but it went by really fast!

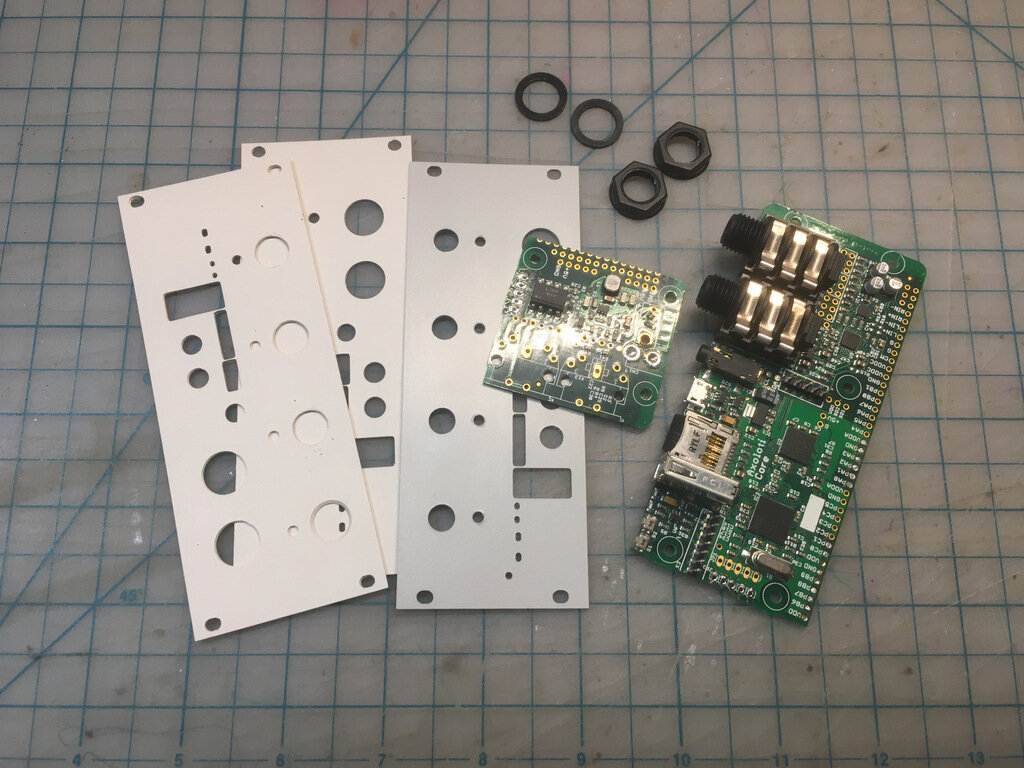

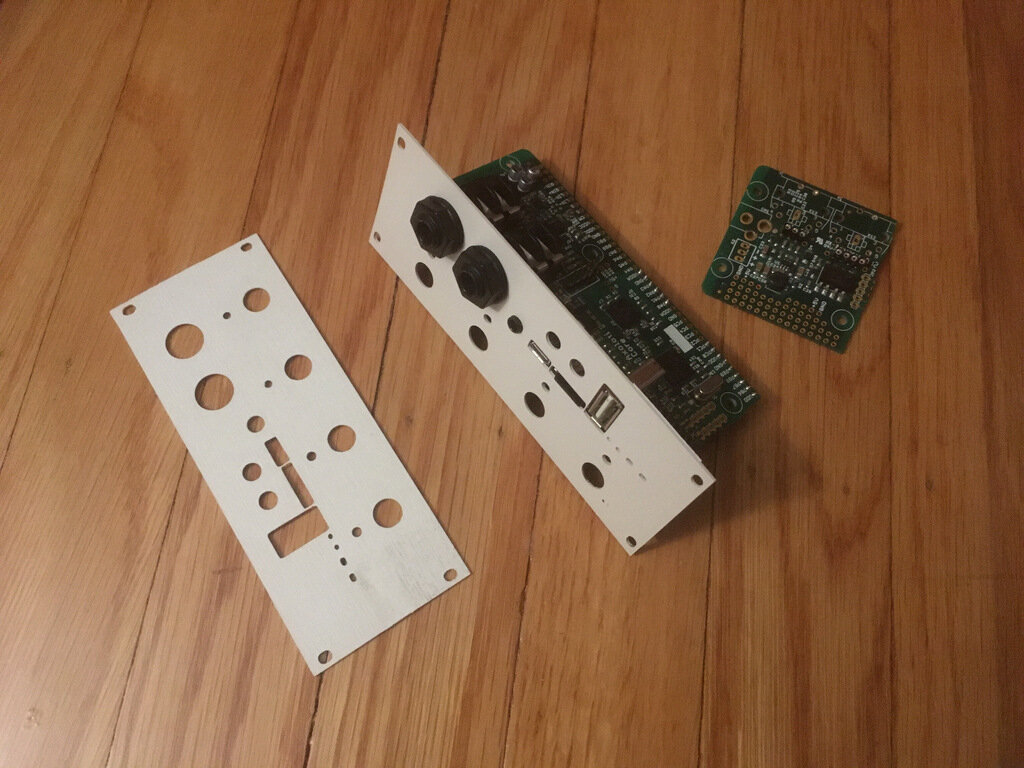

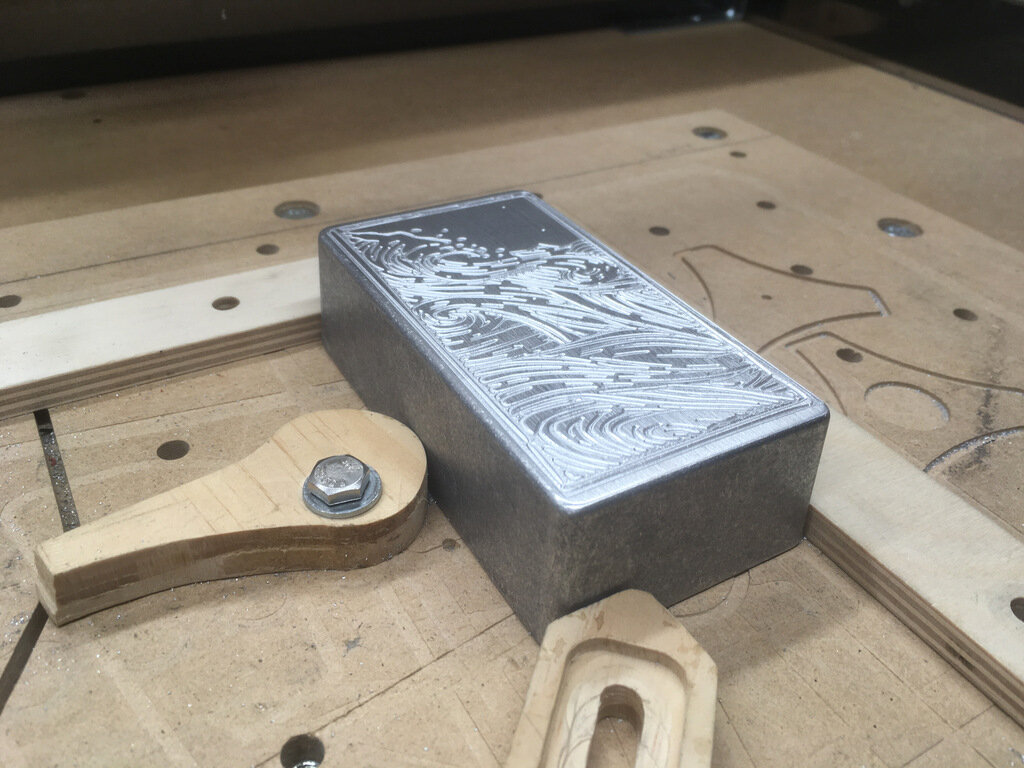

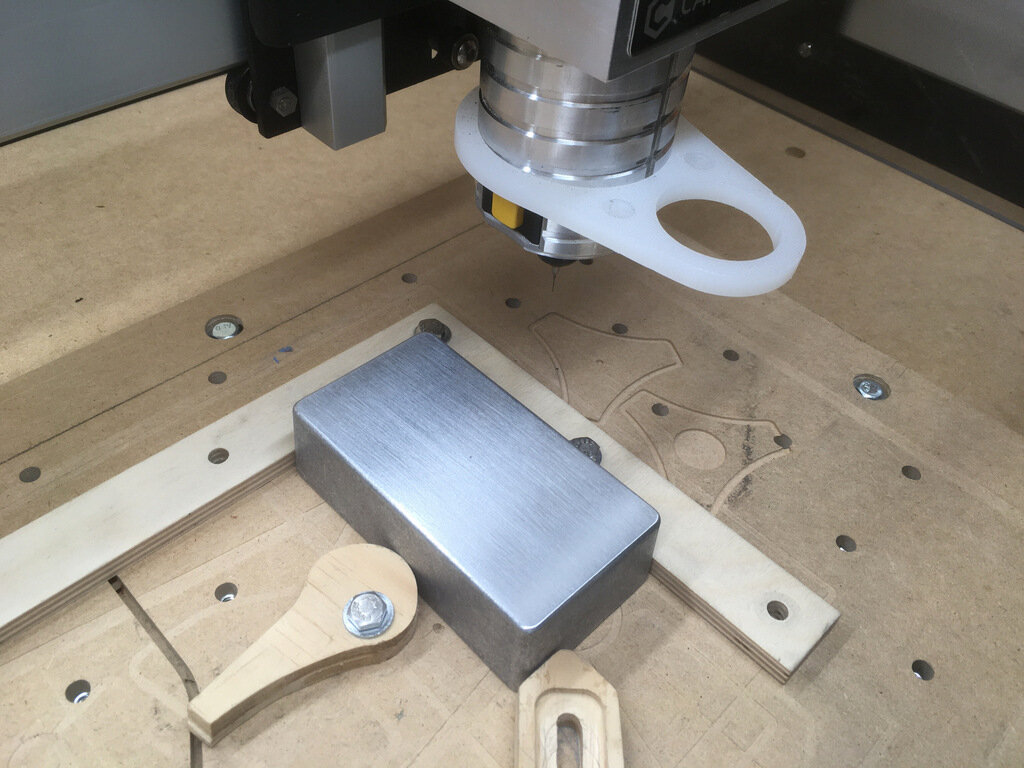

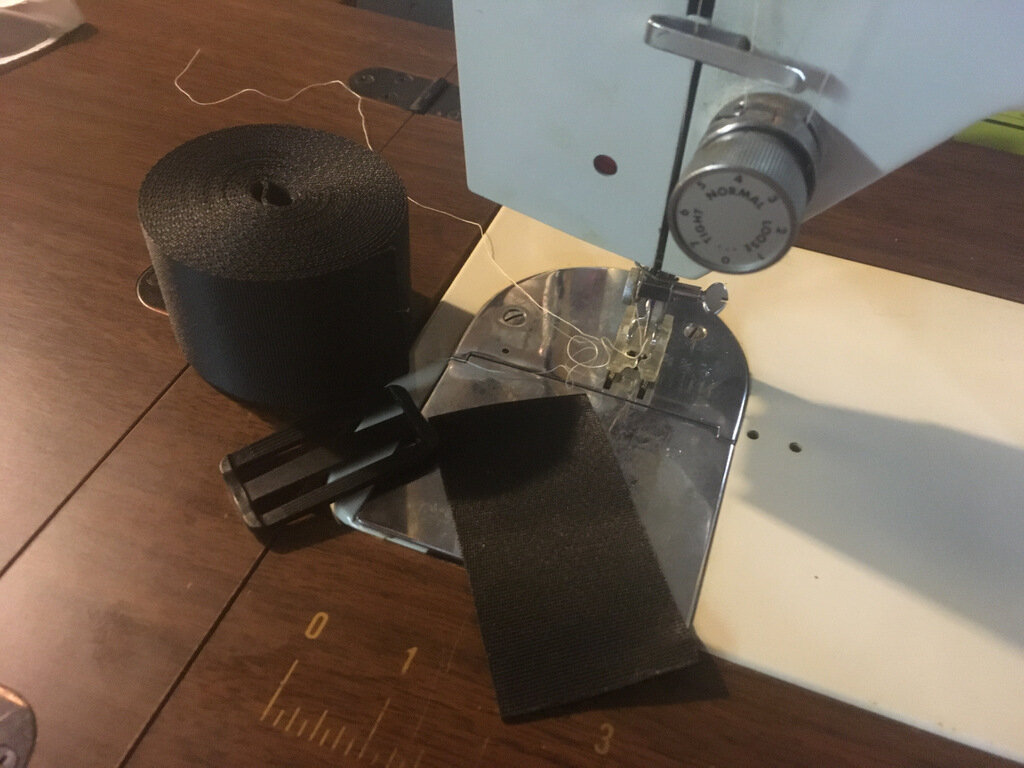

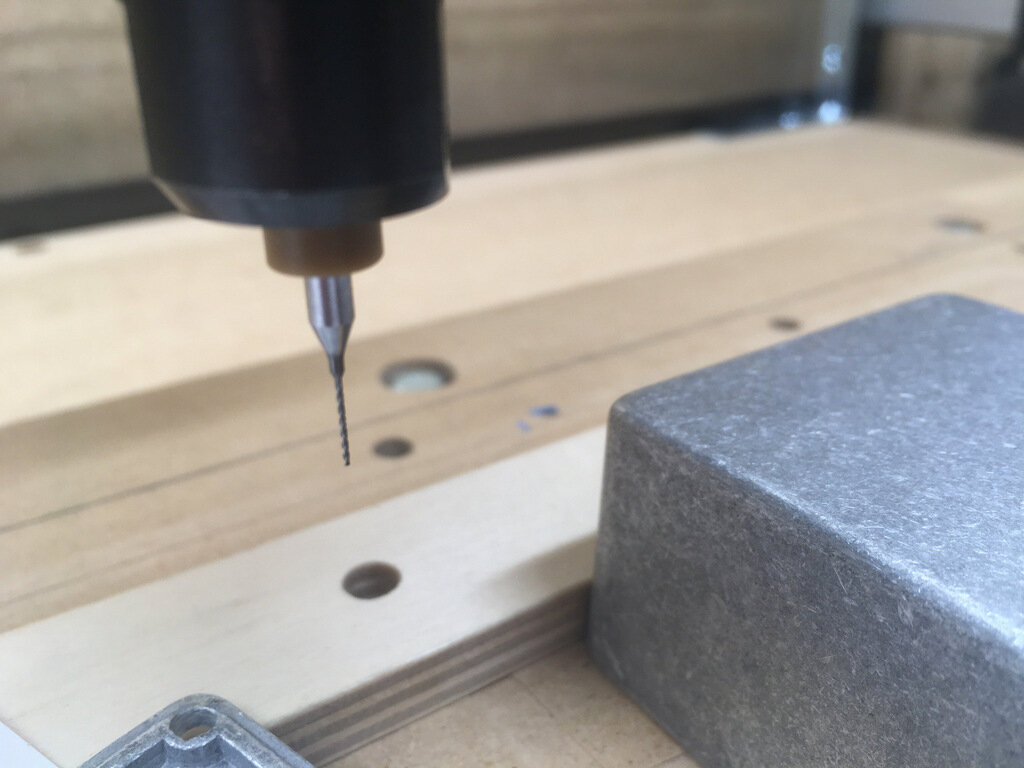

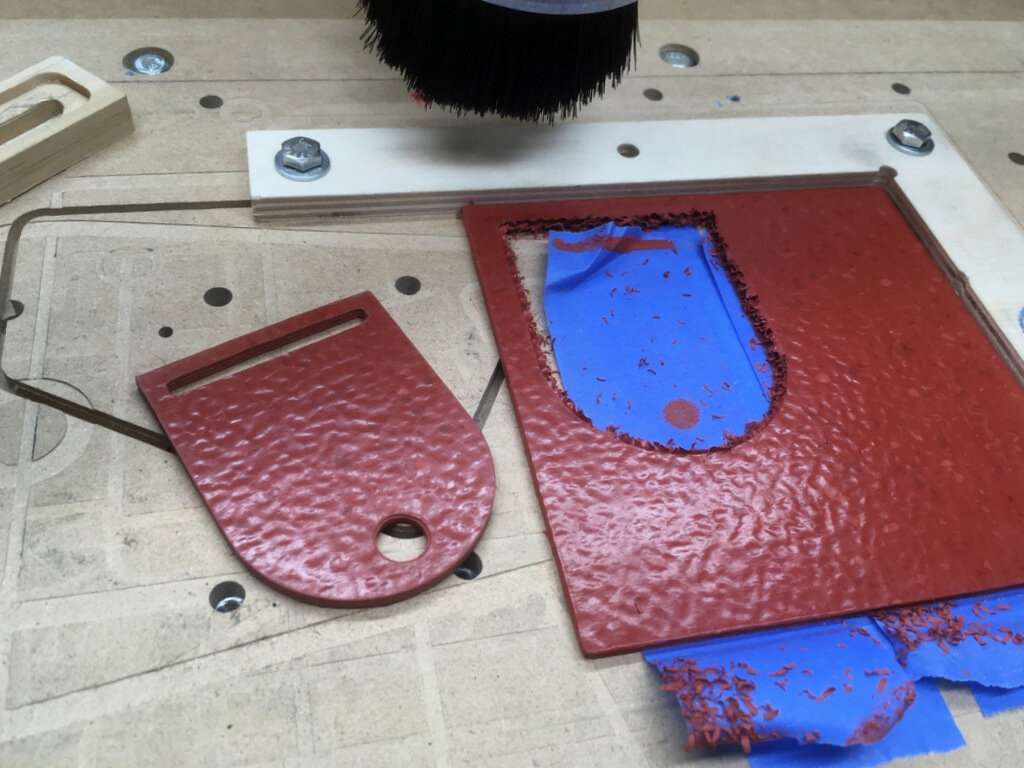

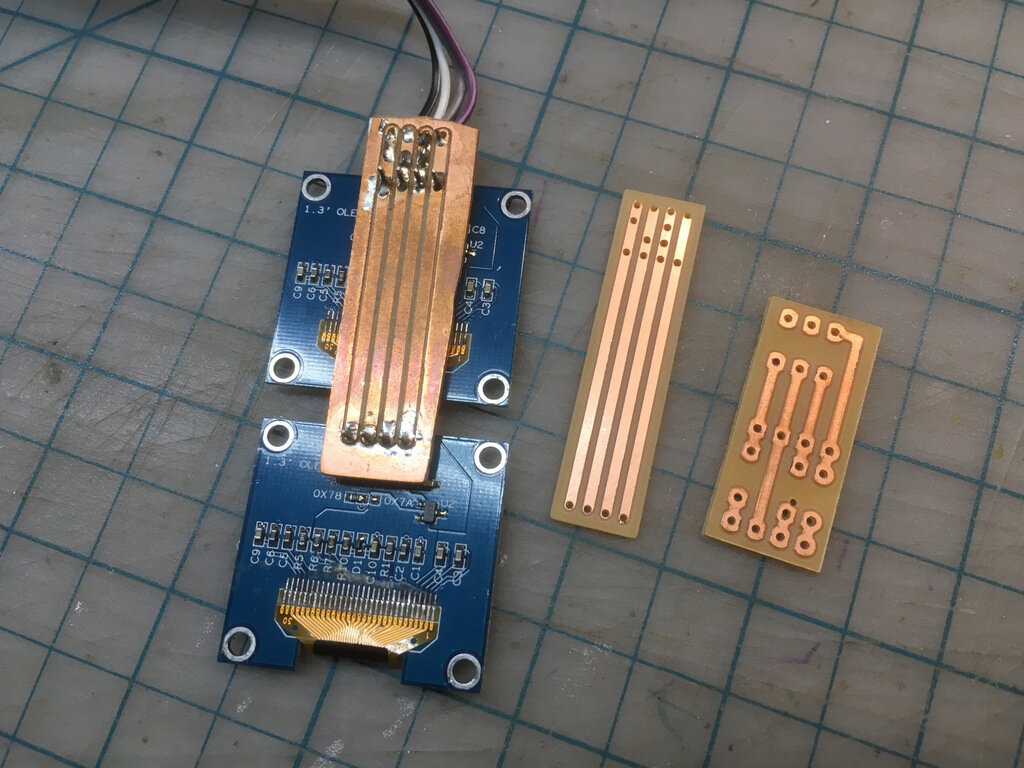

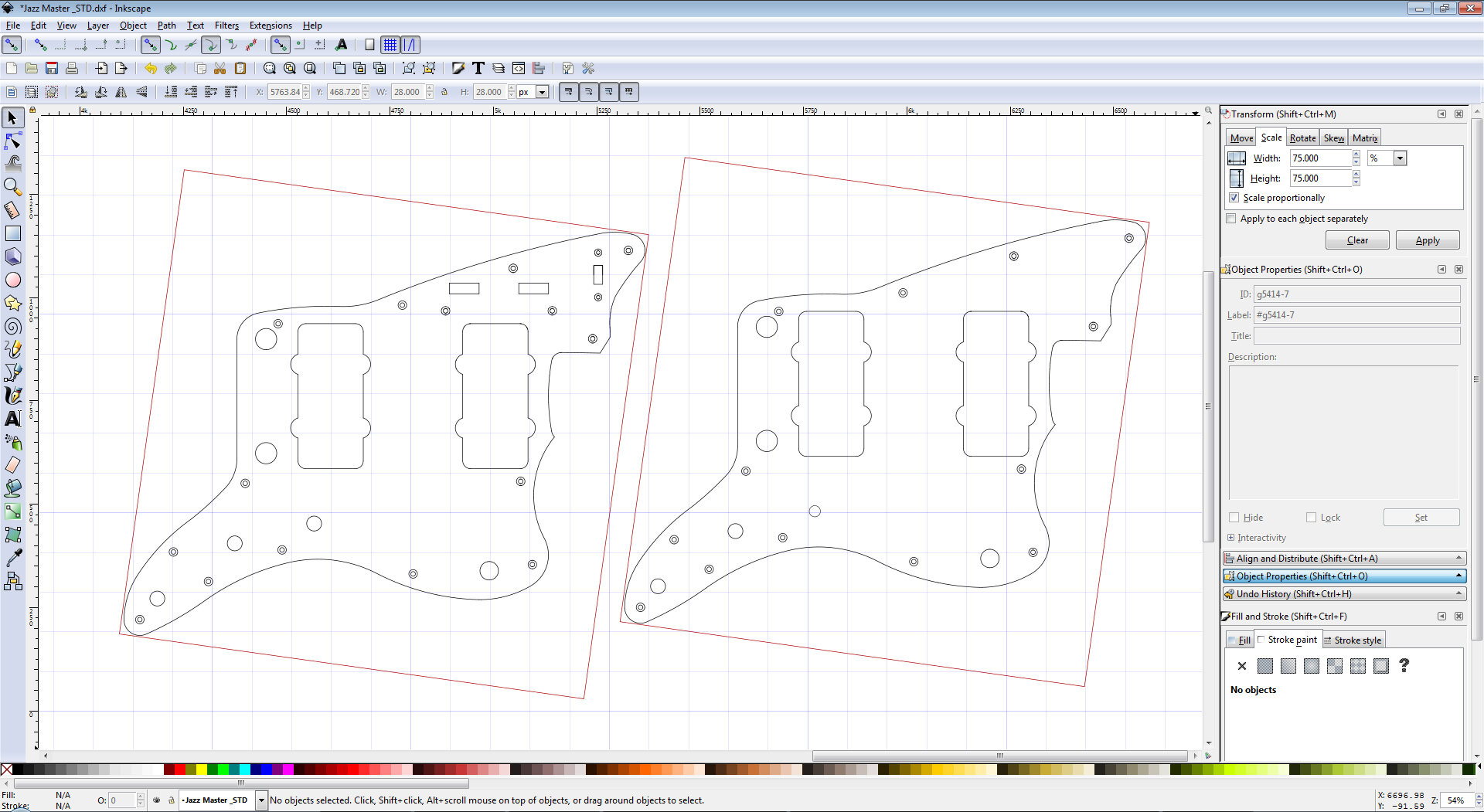

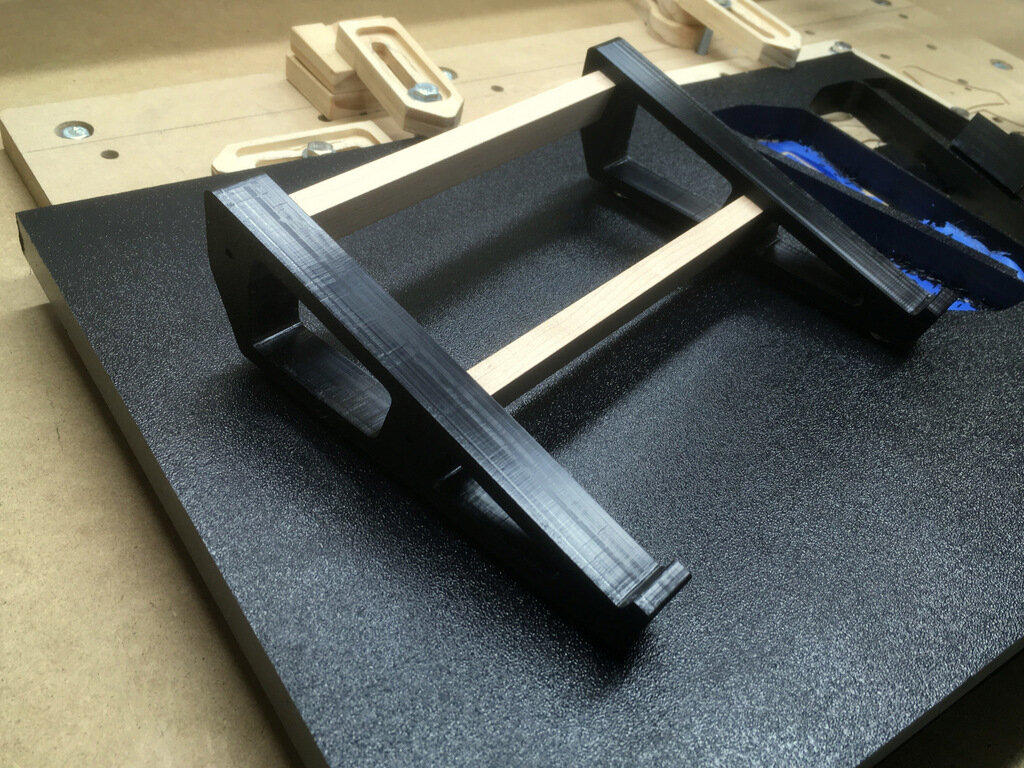

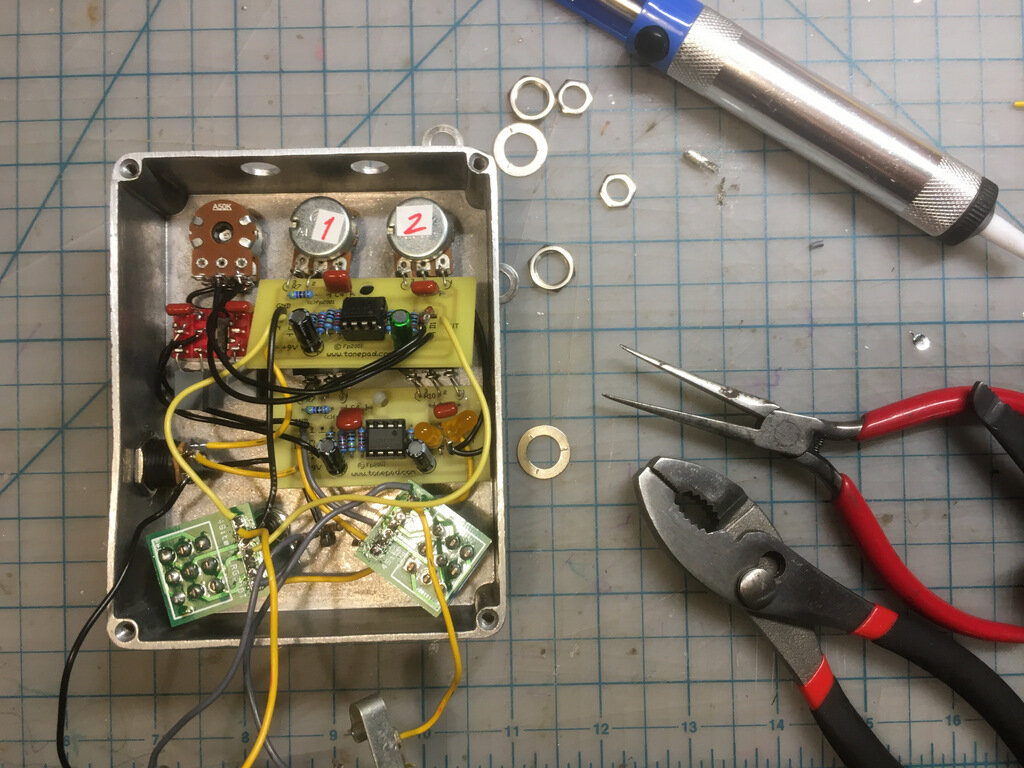

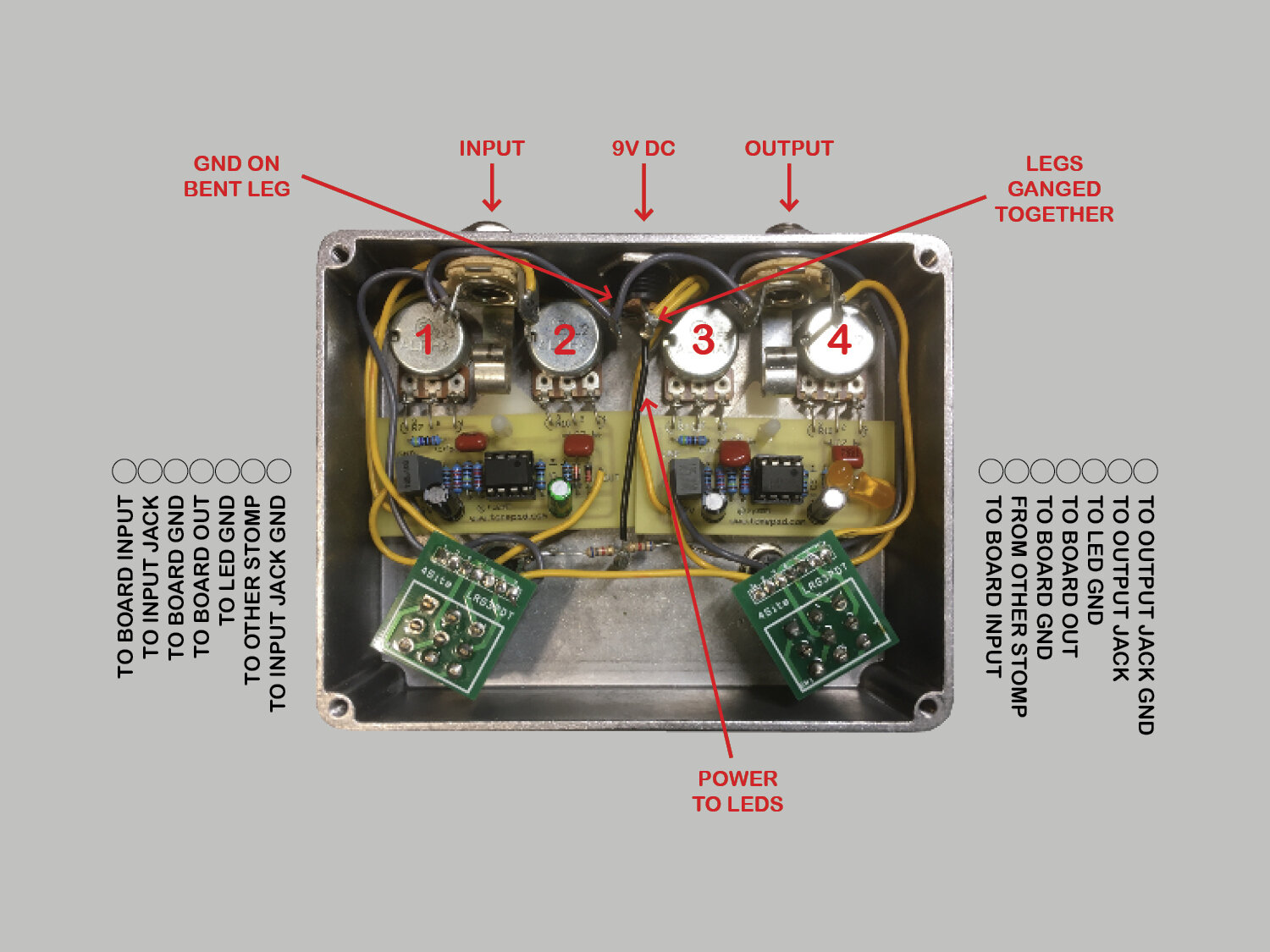

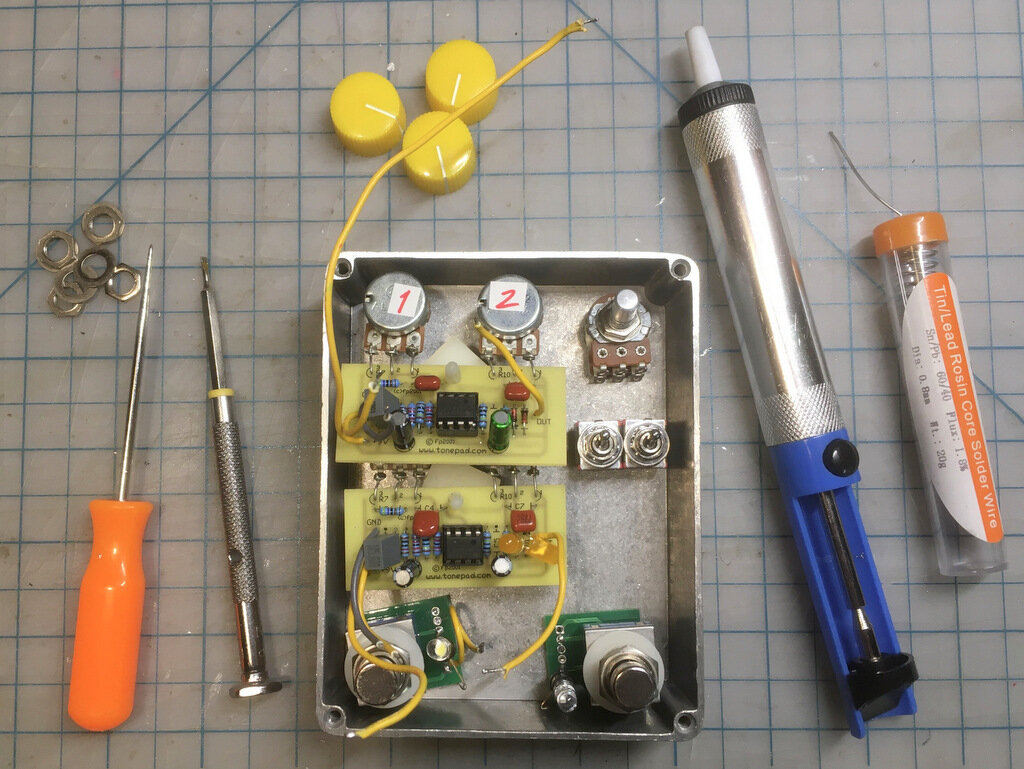

Tonight I managed to cut another faceplate for moduloti and get so so much desoldering done so I can finally get this thing all the way together and working with the encoders and LEDs. I was really itching to patch a bit tonight, but getting this done and back in the rack will be worth it.